High Speed

Manufacturing of electrical stampings and laminations requires precision and efficiency. And when it comes to achieving high production rates, a high-speed manufacturing line is the way to go.

At our state-of-the-art facility, we have installed high speed line ranging from 60 Ton to 550 Ton, which enable us to produce stampings at an astonishing rate. Our HD350 Ton high speed line, in particular, is a marvel of modern engineering. Manufactured by INGYU, it boasts an impressive speed range of 120 – 400 SPM.

What sets our high-speed press line apart is our use of progressive tools. With these tools, we can produce complex laminations with ease, thanks to their auto-stitching and auto-skewing capabilities. These advanced features ensure that our stampings are of the highest quality, with close tolerances and minimal waste.

In short, our high-speed line is the perfect solution for businesses looking to boost their production rates without sacrificing quality. With our state-of-the-art equipment and skilled workforce, we can handle even the most challenging laminations projects.

Press Shop

Our facility boasts of advanced conventional press machinery with an impressive capacity of up to 400 tons, allowing us to cater to your diverse production needs with ease. Our press shop is equipped with the latest servo feeder mechanism, which enables us to produce diameters of up to 1200 mm in a single blow blanking. We take pride in our gang slotting operation, which allows us to create stampings up to 800 mm in diameter in a single blow. In the segmental lamination’s domain, we can produce stampings up to 1200 mm in size, making us a one-stop-shop for all your stamping needs.

Notching

One area where we truly excel is our Notching process. Equipped with the latest technology and cutting-edge equipment, our notching machines are capable of producing laminations up to 1300mm in diameter with skip notching facility and skewed laminations for special applications.

But what really sets us apart is our commitment to precision. Unlike many other manufacturers, we use only servo-driven notching machines that offer unmatched accuracy and consistency. This assures that every stamping we produce is notched to perfection, ensuring optimal performance and reliability.

Whether you need high-volume production or customized solutions, our Notching process is equipped to handle even the most challenging projects. And with our team of skilled professionals and extensive quality control processes, you can rest assured that every lamination we produce will meet or exceed your expectations.

TOOL MANFACTURING AND SERVICING ROOM

At Magcore, we hold ourselves to the highest standards when it comes to the quality of our products and services. Our commitment to quality is evident in our Tool and Mould department, where we manufacture punching tools and die-casting moulds individually to ensure the utmost precision and accuracy.

By producing our tools and moulds in-house, we can closely monitor every step of the manufacturing process, ensuring that each component meets our rigorous standards. Our tools and moulds not only achieve the highest level of quality, but they are also closer tolerances, resulting in superior performance and longer lifespan.

We offer a comprehensive range of services in tool and mould making, including technical consultation, development, construction, manufacturing. Our team of experts uses the latest production and design technologies using 3D software and stimulation techniques to ensure that our tools and moulds are at the cutting edge of the industry.

Our many years of expertise combined with state-of-the-art technical facilities mean that we are also able to implement even the most complex and unusual geometrical requirements.

At our in-house tool making facility, we are using Camut grinding machines capable of re-sharpening tools with a length of up to 3000mm and a width of 1000mm, while still maintaining a high level of accuracy.

Cleating and Welding Process

One of the most critical steps in our manufacturing process is cleating and welding. Our hydraulic press, with a capacity ranging from 40 to 300 tons, is equipped with a roller fixture facility that enables us to cleat stator stacks up to a core length of 1000mm and 950mm in diameter. This ensures that our products are built to precise specifications, resulting in exceptional performance and durability.

To further enhance the quality of our core building process, we offer TIG and MIG welding process. Our team of skilled welders is well-versed in the latest welding techniques and can meet our clients’ specific welding specifications. We take great care to ensure that our welding process is executed with the utmost precision, resulting in a product that is free of defects and ready to perform at its highest potential.

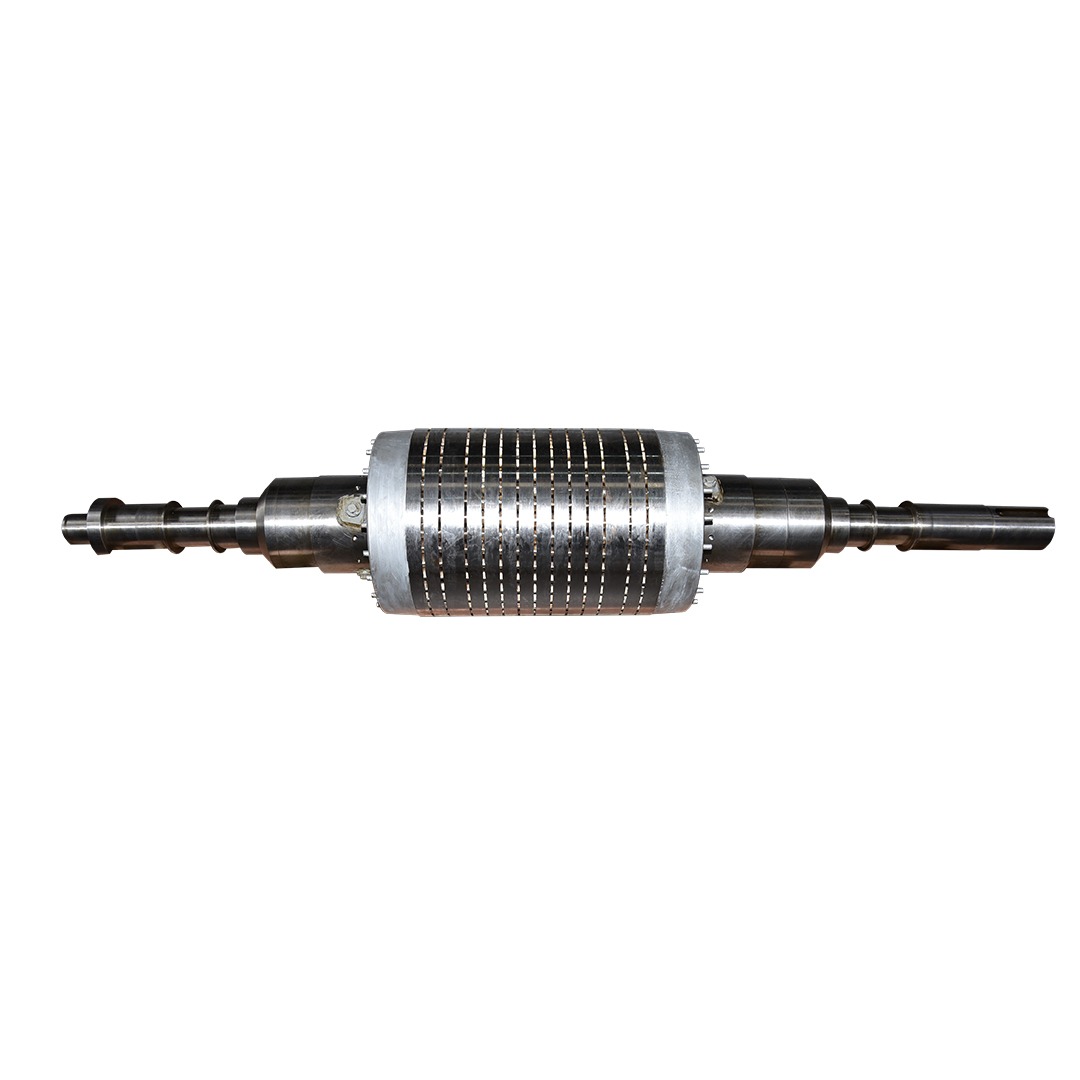

Rotor Die casting Process

At our state-of-the-art manufacturing facility, we specialize in the production of rotor die castings using a variety of materials including aluminium, LM series (aluminium alloy), and copper. Our versatile machinery includes both vertical and horizontal die casting machines, each offering unique capabilities to meet the varying needs of our customers.

For larger rotors, our 630-tons vertical die casting machine is the ideal choice and this is unique facility in the country, capable of producing rotors up to 450mm in diameter and up to 1200mm in length. The maximum weight of molten aluminium we can handle is 145 kgs per shot. For smaller rotors, our 75-tons vertical die casting machine is the perfect solution. Additionally, we have multi-cavity horizontal die casting machines that are specifically designed to produce tiny sized rotors, making them perfect for use in electrical and white goods industry. We are capable of manufacturing and supplying die-cast rotor with shaft insertion.

Input Material

Our commitment to excellence begins with the careful selection of raw materials that form the foundation of our products.

We procure our CRNO silicon steels for laminations and stampings from leading domestic and international mills, including SAIL and POSCO Mills. Our focus on quality extends to our sourcing process, where we carefully select the best grades of CRNO silicon steels, taking into consideration various factors such as thickness, size, coating and grade.

In addition to our CRNO silicon steels, we also use high-purity Aluminium EC grade ingots sourced from top domestic suppliers. Our team of experts ensures that all raw materials undergo thorough inward inspections and are validated at our material testing labs along with test certificate of the mill before their usage. This stringent process assures the superior quality and performance of our products and ensures that they meet the highest industry standards.

Material Cutting & Slitting

We have invested in state-of-the-art material cutting and slitting equipment that delivers the highest standards of dimensional and accuracy and precision.

Our in-house slitting facility can handle coils from 35mm to 1300mm in width, with a thickness ranging from 0.2mm to 2mm. Our equipment is capable of achieving close tolerances, ensuring that the final product meets even the most stringent specifications.

Moreover, our shearing facilities can accommodate coils and sheets up to 3mm thick and 2 mm in width. With our advanced shearing capabilities, we can ensure that the material is cut to the exact size required, allowing for efficient and accurate manufacturing of electrical laminations.